Pressure Swing Adsorption, Newborn Oxygen

In numerous fields such as healthcare and industry, the stable supply of oxygen is of critical importance. From providing life support to patients in hospitals to serving as a key reactant in industrial production, the methods of obtaining oxygen have always been a subject of great concern. The PSA molecular sieve oxygen generator technology, with its unique advantages, has occupied a significant position in the field of oxygen production. It offers an efficient and convenient method for oxygen preparation to various industries. So, what exactly is the principle behind this miraculous oxygen generation technology? Let’s delve into it together.

The Magic “Screening” of Molecular Sieves

Molecular sieves, from their name, seem like a “sieve” with a screening function. In fact, they are substances with a uniform microporous structure, and the size of these micropores is comparable to that of general gas molecules. Different gas molecules, such as oxygen molecules (O₂) and nitrogen molecules (N₂), have differences in size and properties. The diameter of a nitrogen molecule is approximately 0.364 nanometers, while that of an oxygen molecule is about 0.346 nanometers. Although the difference is slight, molecular sieves can keenly capture this distinction. Molecular sieves have a stronger adsorption capacity for nitrogen molecules because their internal crystal structure and surface properties are more compatible with nitrogen molecules. When air passes through the molecular sieve, nitrogen molecules are more easily adsorbed in the micropores of the molecular sieve, while oxygen molecules are relatively less adsorbed, thus achieving an initial “screening” of oxygen and nitrogen.

Oxygen-Nitrogen Separation under Pressure Changes

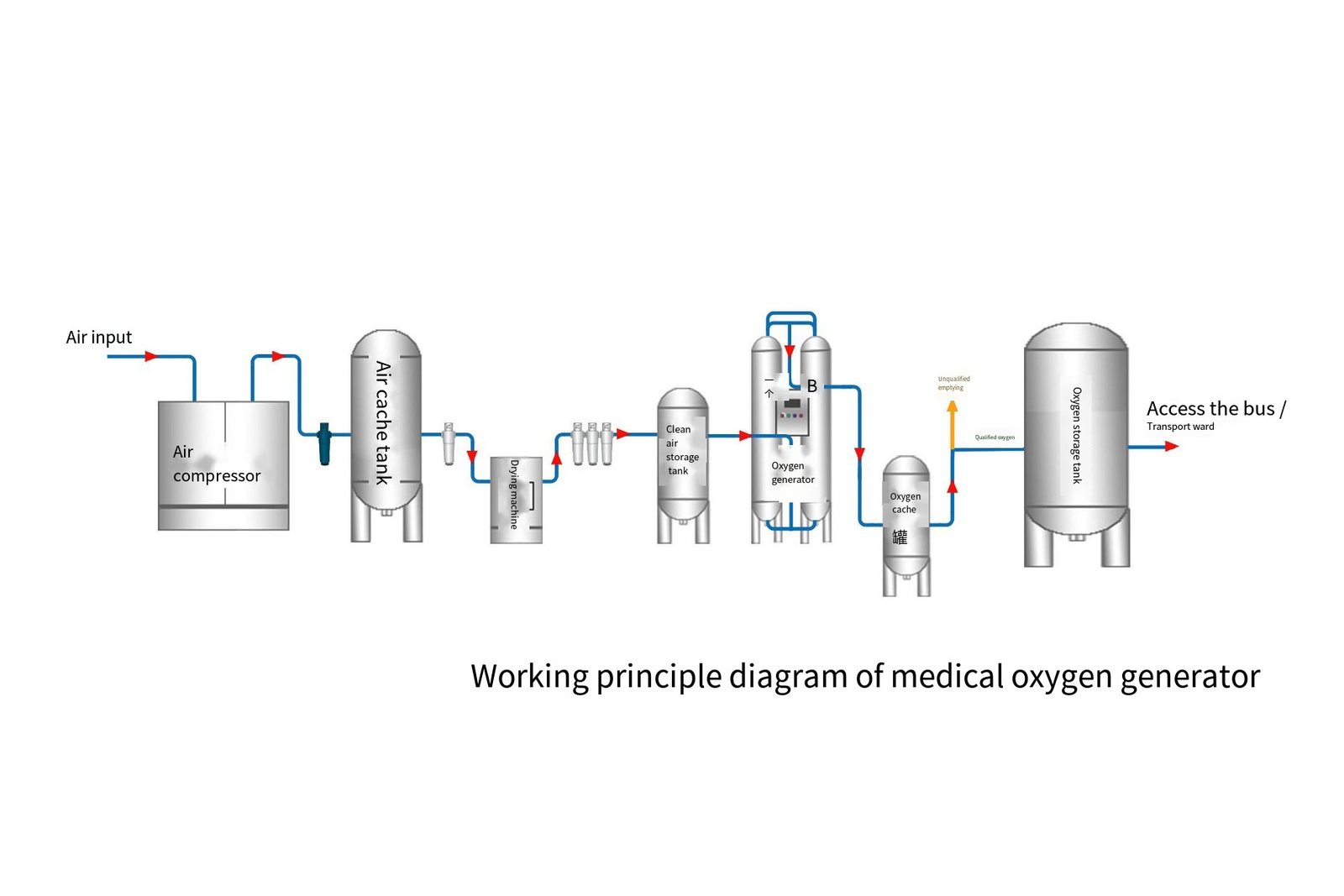

Pressure Swing Adsorption (PSA) is the core working mechanism of the PSA molecular sieve oxygen generator. When the pressure increases, the adsorption capacity of the molecular sieve for nitrogen molecules enhances, and a large number of nitrogen molecules are adsorbed in the micropores of the molecular sieve. At this point, the oxygen content in the gas passing through the molecular sieve relatively increases, achieving the initial enrichment of oxygen. When the pressure decreases, the adsorption capacity of the molecular sieve for nitrogen molecules weakens, and the adsorbed nitrogen molecules are desorbed from the micropores of the molecular sieve, allowing the molecular sieve to regenerate and prepare for the next round of adsorption. In this process, time control is crucial. If the adsorption time is too short, nitrogen molecules cannot be fully adsorbed, resulting in low oxygen purity. If the adsorption time is too long, it will reduce the oxygen production efficiency. Similarly, the desorption time also needs to be precisely controlled to ensure the complete regeneration of the molecular sieve. Through precise regulation of pressure changes and time, the PSA molecular sieve oxygen generator can stably and efficiently separate oxygen.

Advantages and Significance of the Technical Principle

This technical principle based on molecular sieves and pressure swing adsorption endows the PSA molecular sieve oxygen generator with numerous advantages. Firstly, it is highly efficient, capable of rapidly separating oxygen and nitrogen from the air to meet the oxygen demands in various scenarios. Secondly, compared to some traditional oxygen generation methods, the PSA molecular sieve oxygen generator does not require complex chemical reactions or large amounts of chemical reagents, making it more environmentally friendly and free from the production of environmentally polluting by-products. Additionally, it performs well in terms of energy conservation, achieving gas separation through the rational utilization of pressure changes and having relatively low energy consumption. From the perspective of industry development, the emergence of PSA molecular sieve oxygen generator technology has driven the oxygen generation industry towards high efficiency, environmental friendliness, and energy conservation, providing a reliable guarantee for oxygen supply in medical, industrial, and other fields, and promoting the progress and development of related industries.

Leave a Reply